R&D Magnetron Sputtering System—MS-700

The MS-700 magnetron sputtering system is a multifunctional and multi cathode magnetron sputtering system, characterized by ultra-high vacuum and single atomic layer deposition accuracy. Circular cathodes up to 4 inches can be configured according to requirements, with options for vertical sputtering, automatic transmission, reactive sputtering, and film thickness measurement. Suitable for medium to high precision process requirements that require multi target sputtering in research and production.

Key word:

High-accuracy Magnetron Sputtering System, Film Deposition, Process Debugging, Software Development

Category:

R&D Film Deposition Equipment

产品附件:

TEL

R&D Magnetron Sputtering System—MS-700

Details

The MS-700 magnetron sputtering system is a multifunctional and multi cathode magnetron sputtering system, characterized by ultra-high vacuum and single atomic layer deposition accuracy. Circular cathodes up to 4 inches can be configured according to requirements, with options for vertical sputtering, automatic transmission, reactive sputtering, and film thickness measurement. Suitable for medium to high precision process requirements that require multi target sputtering in research and production.

Performance Parameters

| Wafer size | 4inch-6inch |

| Uniformity |

Better than±2% |

| Extreme vacuum |

Better than 5×10-10mbar(metal seal ) |

| Heating Temperature | RT-800℃,maximum 1200℃ |

| Number of cathodes | Twelve 2-inch cathodes or six 4-inch cathodes , Co-sputtering |

| Power supply | DC、RF、DC Pulse |

| Accuracy | 0.1nm |

| Space | 4m L*3m W*2.5m H |

| Options | Cryogenic pump, vertical sputtering, automatic transfer, reactive sputtering, QCM, RGA, process menu etc. |

Test case series

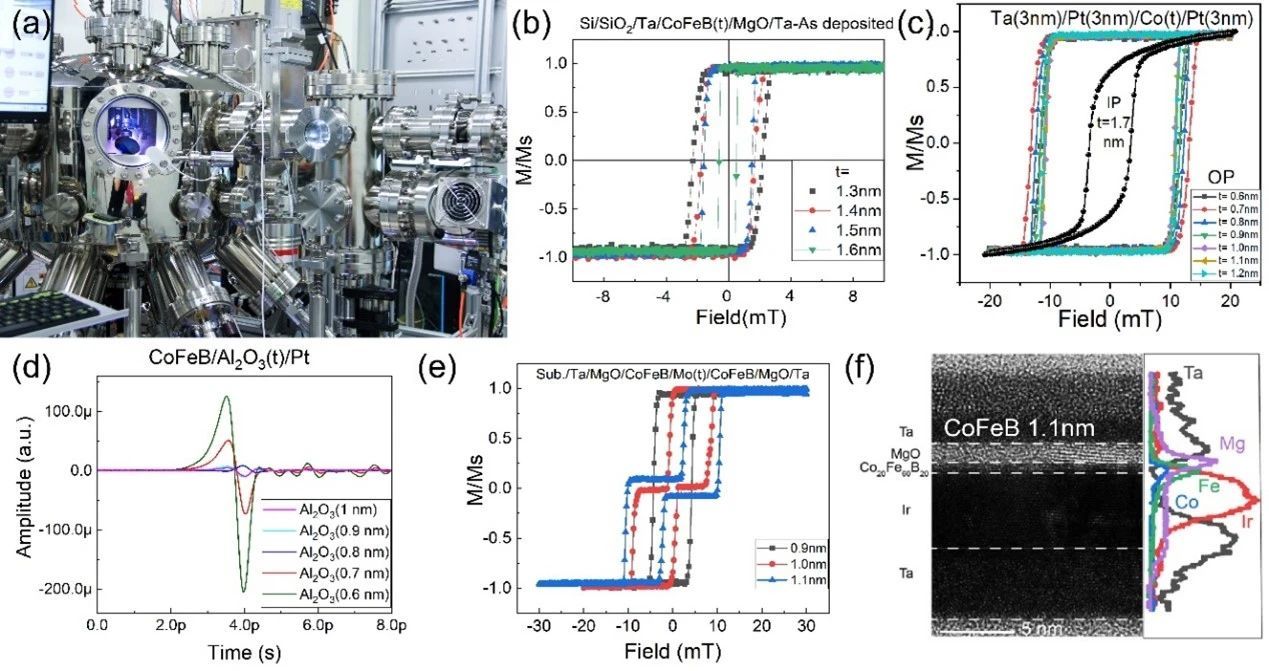

Figure 1 shows the magnetic characterization results of Pt/Co and CoFeB/MgO multilayer films deposited on MS-700 equipment. It can be seen that a significant change in the magnetic properties of the sample can be observed by changing the thickness of the 0.1nm magnetic layer, which proves that the equipment can achieve thin film deposition with an accuracy of 0.1nm.

Figure 1 (a) Physical image of MS-700 magnetron sputtering equipment; (b) Magnetic characterization results of CoFeB/MgO system; (c) Magnetic characterization results of Pt/Co system; (d) Terahertz excitation characterization results of CoFeB/Al2O3/Pt system; (e) RKKY characterization results of CoFeB/Mo/CoFeB system; (f) Scanning tunneling microscopy characterization results of Ir/CoFeB/MgO/Ta system.

In addition, in the CoFeB/Pt terahertz excitation experiment, in order to demonstrate the influence of the interface between the two on the terahertz excitation signal, a layer of Al2O3 was inserted between the two. From Figure 1 (d), it can be seen that as the thickness of the Al2O3 layer changes by 0.1nm, the terahertz excitation signal also undergoes significant changes. Furthermore, in the CoFeB/Mo/CoFeB system, by changing the thickness of the Mo layer, it can be observed that the RKKY coupling of the film also undergoes a transition in strength and antiferromagnetic and ferromagnetic coupling (Figure 1 (e)), and the thickness of the deposited film was accurately measured by scanning electron microscopy (Figure 1 (f)). The above experimental results indicate that the resolution of the device for depositing thin films can reach 0.1nm, and the device can achieve atomic level deposition resolution.

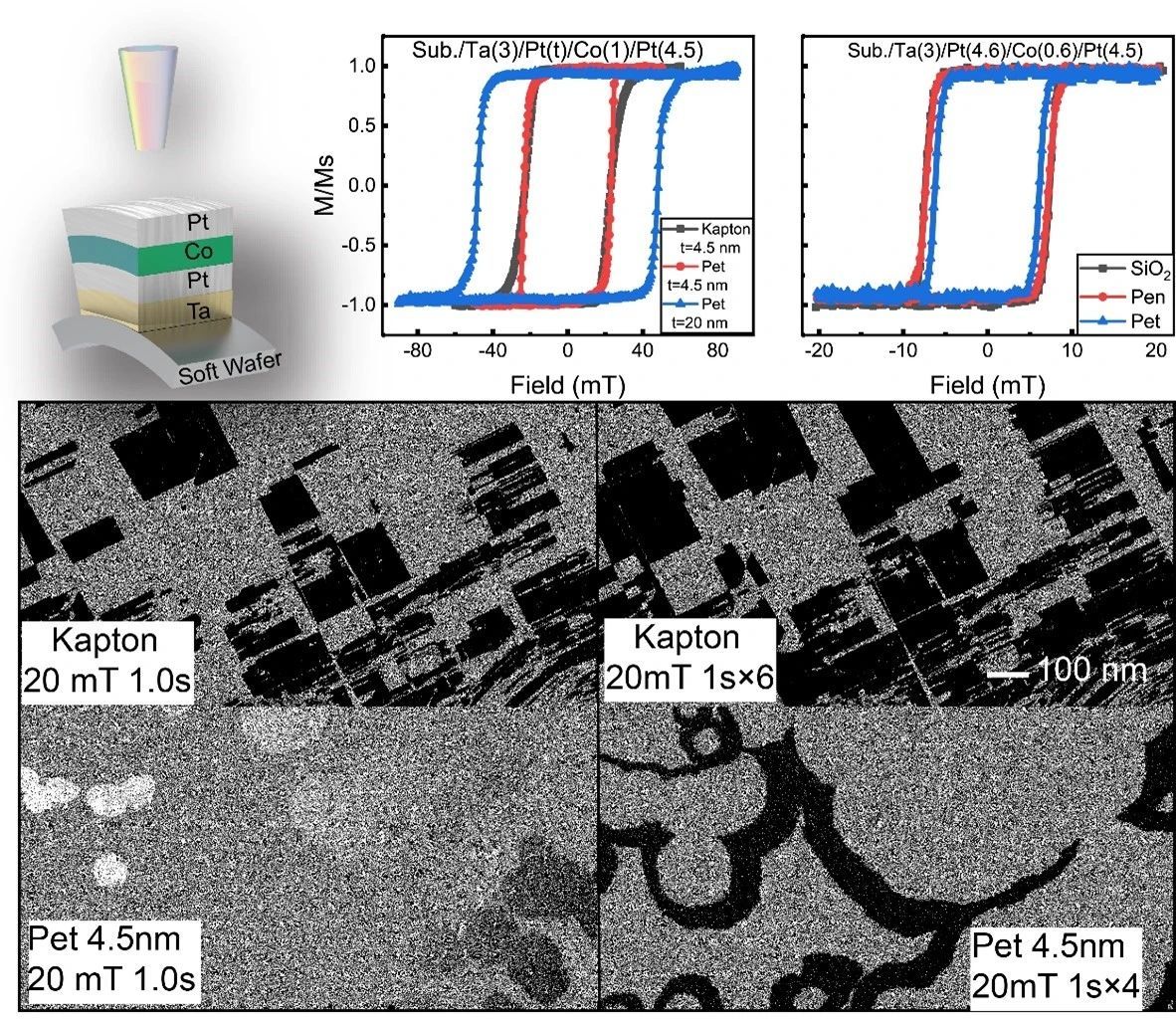

Figure 2 Characterization results of Pt/Co multilayer films prepared by MS-700 magnetron sputtering equipment

By adjusting the growth conditions and interface state of Pt/Co structure, spin multilayer films with high vertical magnetic anisotropy were successfully grown on flexible substrates using MS-700 equipment.

Previous

Related products

Production Grade Multifunctional Thin Film Deposition Equipment

This equipment is based on the wafer vacuum transfer platform VTM and can be flexibly equipped with transfer chambers and process chambers. The process chambers can be optionally equipped with electron beam evaporation chambers, molecular beam epitaxy chambers, sputtering chambers, thermal evaporation chambers, and pre cleaning chambers. It can achieve precise deposition of various materials.

R&D Magnetron Sputtering System—MS-700

The MS-700 magnetron sputtering system is a multifunctional and multi cathode magnetron sputtering system, characterized by ultra-high vacuum and single atomic layer deposition accuracy. Circular cathodes up to 4 inches can be configured according to requirements, with options for vertical sputtering, automatic transmission, reactive sputtering, and film thickness measurement. Suitable for medium to high precision process requirements that require multi target sputtering in research and production.

R&D Magnetron Sputtering System—MS-400

This type of magnetron sputtering system is a multi-function and multi-target magnetron sputtering system, which has the characteristics of ultra-high vacuum, single atomic layer deposition accuracy and simple equipment maintenance. The MS-400 system is equipped with six 2-inch confocal ultra-high vacuum cathodes to meet the needs of process research in the laboratory or enterprise laboratory, with simple maintenance and stable operation.

R&D Magnetron Sputtering System - MS-300

The MS-300 magnetron sputtering system has the characteristics of ultra-high vacuum, single atomic layer deposition accuracy, flexible selection of cathode up or down sputtering. The equipment is equipped with three 2-inch ultra-high vacuum cathodes as standard. Meet the needs of laboratory scientific research, with simple maintenance and stable operation.

Provide solutions for your industry and prepare for your choices

info@truthhefei.com

info@truthhefei.com WhatsApp

WhatsApp

+86-13013196967

+86-13013196967